Lex Products Introduces EverGrip Molded Stage Pin Connector

The Stage pin, an industry favorite and considered by many the best connector for us. It has been around since the early 20th century. Little has changed in the over all design since it was introduced. Sure, we have some up with better materials and secure wire connections.

The Stage pin, an industry favorite and considered by many the best connector for us. It has been around since the early 20th century. Little has changed in the over all design since it was introduced. Sure, we have some up with better materials and secure wire connections.

There has always been the issue of bent pins, thus requiring a pin tool or the old air gap impedance problem from connections slipping apart.

Lex Products has come up with a way to fit all of those little announces with the new EverGrip Molded Stage Pin Connector. Lex developed the EverGrip Molded Stage Pin Extension and safety shroud in response to industry research, which revealed crushed and bent pins were the primary cause of stage pin connector failure, resulting in poor connections between male and female devices.

Exclusive Safety Shroud for Extra Connector Pin Protection: The spring-loaded shroud features a lock button that fastens the shroud in the forward position to prevent damage to pins, or in the retracted position for easy mating with panel mount receptacles. A separate connector lock button fastens male and female inline connectors together when mated to prevent accidental disconnection.

Proprietary Construction: The new EverGrip Molded Stage Pin Extensions, available in 60 and 100 Amp ratings, contain thermoset resin contact carriers, which resist electrical tracking and can withstand higher temperatures caused by overload or arcing. Lex Products’ exclusive premold design bonds the cable and connector together to deliver superior strain relief and secure terminations. An impact resistant thermoplastic elastomer overmold prevents internal damage to pins and contacts and is insulated for safe handling.

Designed for Ease of Use and Extended Cable Life: An exclusive, ergonomic, tapered hand grip provides a firm gripping surface for easy connector mating and unmating. The extension’s rugged, one-piece connector construction inhibits infiltration of contaminants and eliminates joints and loose assembly screws. A UV-stabilized thermoplastic elastomer exterior prevents connector housing degradation when used outdoors.

The new EverGrip Molded Stage Pin Extension is expected to begin shipping mid summer 2012. Learn more at www.lexproducts.com.

Lex Products Adds Molded Motor Control Cables to EverGrip Line

Lex Products announces the addition of Molded 7 and 14 Pin Motor Control Cable to its growing line of EverGrip cable assemblies. Lex’s overmold technology provides enhanced safety and durability for critical motor and hoist applications used in Entertainment scenery and rigging. The cables feature 7 and 14 pin Veam compatible quarter turn motor configuration connectors and heavy-duty 16AWG 7 conductor SOOW cable.

Lex Products announces the addition of Molded 7 and 14 Pin Motor Control Cable to its growing line of EverGrip cable assemblies. Lex’s overmold technology provides enhanced safety and durability for critical motor and hoist applications used in Entertainment scenery and rigging. The cables feature 7 and 14 pin Veam compatible quarter turn motor configuration connectors and heavy-duty 16AWG 7 conductor SOOW cable.

The core of EverGrip is a polypropylene premold which provides a mechanical bond between the cable and connector and totally encapsulates the contacts and conductors to prevent the possibility of pushed pins, and broken conductors. Short circuits due to stray wires are eliminated. A solid Santoprene overmold absorbs impact to protect internal conductors and provides enhanced flex and strain relief to extend cable life.

Standard length cable assemblies are available from 5ft. thru 200ft. Custom cable lengths and cable labels can also be specified. Lex can also retrofit new EverGrip molded connectors to your damaged motor cables, extending the life of your cable.

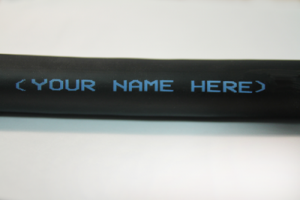

To help reduce potential losses do to mixing of dealers cable on job sites and to increase dealers brand identity, the customer’s name or logo can be molded into each connector body for a nominal charge.

Lex offers a 5 year limited warranty on EverGrip molded male and female connectors. Lex also molding of names and logo’s on the connectors of the cables. To learn more about the new Molded Motor Control Cables, visit Lex Product’s website at www.lexproducts.com.

Lex Products Offers Custom Printing on EverGrip Cables

Lex Products can now provide custom legend printing up to 50 characters on your choice of EverGrip˙ overmolded or traditional LSC19 pin multi-cable assemblies.

Lex Products can now provide custom legend printing up to 50 characters on your choice of EverGrip˙ overmolded or traditional LSC19 pin multi-cable assemblies.

Build brand identity, deter theft and prevent mixing of cables by printing your company name, phone number, part numbers or other important information spaced every 2 ft. along the entire length of cable.

The bold type 1/8″ characters are printed in sky blue ink for high visibility.

Custom legend printing can be provided on 12/14, 12/18, 14/14, and 16/18 multi-cable extensions at no additional charge with a minimum order of 1000 ft. of cable.

To learn more about custom labeling on EverGrip products, visit Lex’s website at www.lexproducts.com.

Lex Products adds Break-Ins and Breakouts to EverGrip Line Up

Lex Products has announced the addition of molded 6 -circuit Break-Ins and Break-Outs to its recently launched EverGrip™ line of Multi-Cable Assemblies. The cable assemblies feature Lex Socapex compatible connectors which go through two separate molding processes to ensure they can stand up to the most demanding stage and studio applications.

Lex Products has announced the addition of molded 6 -circuit Break-Ins and Break-Outs to its recently launched EverGrip™ line of Multi-Cable Assemblies. The cable assemblies feature Lex Socapex compatible connectors which go through two separate molding processes to ensure they can stand up to the most demanding stage and studio applications.

The core of EverGrip™ is a polypropylene pre-mold which provides a mechanical bond between the cable and connector and totally encapsulates the contacts and conductors to prevent the possibility of pushed pins, broken conductors and damaged ground rings. A solid Santoprene™ over-mold absorbs impact to protect internal conductors and provides enhanced flex and strain relief to extend cable life.Lex offers a 5 year limited warranty on LSC19 molded male and female connectors.

Break-Ins and Break-Outs are offered with a variety of Edison straight blade, NEMA locking, or Bates® connectors, including 5-15, L5-20, and L6-20 configurations. Standard lengths include 3FT, and 6FT. Staggered and custom cable lengths and connectors can also be specified.

To learn more about the Lex Break-in and Breakout EverGrip series, visit their web site at www.lexproducts.com.

LatestHeadlines

- Upgrading Your Toolbox: City Theatrical DMXcat-E and DMXcat Multi Function Test Tool

- Claypaky Bringing Back the Sexy to Par Cans with the Midi-B FX

- Ayrton Evolves the Cobra, the Cobra2 Developed for the US Market

- MA Lighting Intros grandMA3 onPC Fader Wing and DIN-Rail Nodes

- Live Events LEVL Up Fest: A Festival to Aid our Industry