Wenger Corporation Acquires Rigging Company, J.R. Clancy

More from the Press Release:

Effective August 1, 2011, the Wenger Corporation, based in Owatonna, MN signed an agreement to acquire J.R. Clancy, Inc. based in Syracuse, NY.

This is exciting news for employees and business partners of both companies. The Wenger Corporation and J.R. Clancy are long standing privately owned businesses with shared values, dedicated and loyal employees, great brands, strong heritages, and great reputations in the market place.

It is our intent to operate these companies as complementary businesses. J.R. Clancy, led by Bob Theis and Mike Murphy, will remain J.R. Clancy. Wenger, led by Bill Beer, will remain Wenger. The headquarters of J.R. Clancy will remain in Syracuse and the headquarters for Wenger will remain in Owatonna.

Clearly, we anticipate that each business will benefit in the form of increased sales, broader depth and breadth of products, development of new markets, shared leverage and resources, and shared best practices. We are excited about joining these two great companies. This is a great transaction for both companies. Even more importantly, it is a great transaction for the employees of both companies!

JR Clancy Offers New Rigging Hoists; PowerLine, StageHand, StageHand+, Titan

JR Clancy continues to evolve the world of stage rigging and motor control with their latest line of products. JR Clancy just announced four new products to their lineup. The PowerLine Line Shaft Hoist, StageHand Manual Hoist, StageHand+ Motorized Hoist and the Titan Automated Hoist.

PowerLine

PowerLine

The PowerLine provides a wide range of speeds and capacities, making it a versatile performer. Applications include scenery, lighting sets, curtains, and front-of-house lighting. These hoists have minimal side loading on the building structure, simplifying building steel and making these hoists excellent for retrofits in older buildings. Learn more about the PowerLine Line Shaft Hoist by downloading the spec sheet.

StageHand

StageHand

StageHand you get extraordinary lifting capacity for an economical price. Manual utility hoists for access to lighting sets, masking curtains, and other items that do not move as part of a performance. The hoist can be padlocked for security. The StageHand hoist shall not be used to lift humans. Learn more about the StageHand Hoist by downloading the spec sheet.

StageHand+

StageHand+

StageHand+ you get extraordinary lifting capacity for an economical price. A motorized utility hoists for access to lighting sets, masking curtains, and other items that do not move as part of a performance all at the push of a button. The hoist can be padlocked for security. The StageHand hoist shall not be used to lift humans. Learn more about the StageHand Hoist by downloading the spec sheet.

Titan

Titan

Clancy has been building big, custom performance hoists for many years. The Titan hoist is a semi-custom hoist providing high speed and high capacity in a compact package. These performance hoists are used in major performing arts centers, opera houses, and concert halls. Learn more about the Titan Hoist by downloading the spec sheet.

You can always visit JR Clancy’s website at www.jrclancy.com to learn more and to get system quotes.

JR Clancy to Showcase Rigging Projects at USITT in Charlotte

The very latest in rigging technology—from award-winning innovations for a grand opera house to the safest choices for schools—will be showcased in videos at J. R. Clancy’s booth (#730) at the USITT conference in Charlotte, NC, March 9-12, 2011.

J. R. Clancy will feature high-resolution videos of several of its most recent rigging projects in action:

1. The custom-built, 40-foot-high chandelier in the Winspear Opera House in Dallas features 318 cast acrylic rods which vanish as the house lights dim before a production begins. Clancy technology made it possible for the rods to move in synchronized patterns and retract into the ceiling smoothly and rapidly, powered by 44 custom-design winches with up to eight lines per winch. The video provides close-up views of the intricate rigging above the house ceiling while the chandelier’s rods are in motion.

2. Clancy’s PowerAssist™ allows you to motorize new or existing counterweight sets economically. This eliminates handling counterweights, simplifying operations. PowerAssist can be provided with Up / Down pushbuttons, or with the SureTarget™ preset position controller. These are widely used on lighting and orchestra shell ceiling sets where accurate positioning is essential.

3. Imagine changing over from a dance concert’s scenery to an orchestral shell and acoustic canopy in just 47 minutes—using a student crew! At the Miller Performing Arts Center at Alfred University, Clancy’s PowerLift automated rigging system makes even the most complex changeovers easy. You’ll see students operate the PowerLifts using Clancy’s top-of-the-line SceneControl 500 rigging control console, removing dance concert scenery from battens without moving a single counterweight, and hanging pieces of the Wenger Diva shell effortlessly. Preset limits for each batten return the shell to the correct position.

More on J. R. Clancy is available at www.jrclancy.com.

JR Clancy Supports “Roadie for a Day” Boot Camp in Dallas

Have you always wanted to be a roadie? It is a tough life! How would you like to live the life for a day? At this year’s Performing Arts Managers Conference, (PAMC) in Dallas Texas, that dream can come true with the “Roadie for a Day” Boot Camp on Saturday, February 26th.

JR Clancy is leading the sponsorship on the event which will be held at the AT&T Performing Arts Center as part of the International Association of Venue Manager, (IAVM) and the annual PAMC conference. The Boot Camp will be lead by Millie Dixon, principal consultant at Theatre Projects Consultants and the Boot Camp leader, and Alex Hargis, manager of the Wyly Theatre at the AT&T Performing Arts Center. J.R. Clancy personnel and partners also will lead the rigging section to ensure that participants learn the correct and safe way to plan, assemble, and operate standard touring rigging equipment.

For an intensive afternoon, from 12 noon to 4:30 p.m., three teams-each including 20 to 30 venue managers-will learn how to set rigging points, load-in and assemble truss, chain motors, and control equipment, and safely prepare the ‘rig’ for the attachment of the lighting and touring equipment load-in. In addition, team members will hang and cable lights, complete the circuiting, and design two different lighting “looks” on the venue stage.

Each team will work in its own venue at AT&T Performing Arts Center: Margaret McDermott Performance Hall, Hamon Hall in the Bill and Margot Winspear Opera House, and the Dee and Charles Wyly Theatre.

For more information visit www.iavm.org.

JR Clancy Has MORE Scary Rigging Photos on Facebook

How bad can rigging mistakes get? That’s the question J. R. Clancy answers on a weekly basis with its Scary Rigging Photo of the Week, posted on the company’s Facebook page.

How bad can rigging mistakes get? That’s the question J. R. Clancy answers on a weekly basis with its Scary Rigging Photo of the Week, posted on the company’s Facebook page.

The photos of real rigging, sent to Clancy staff members by rigging inspectors and theatre managers, have generated more than one thousand friends to date for the page.

Here’s how it works: Each week, Clancy posts a new photo of a rigging accident-waiting-to-happen at www.facebook.com/JRClancy. These photos stand as vivid examples of amateur errors, often involving hardware that was never meant to bear weight.

The photos are so scary that they’re almost unbelievable, but these frightening scenarios come from real-life high schools, community theatres, worship facilities, and professional performing arts centers.

To see the photos, read comments from rigging professionals about each photo, and add your own comments, visit the J. R. Clancy page on Facebook and click “Like” at the top of the page.

To find a qualified rigging inspector and/or installer in your area, call J. R. Clancy at (800) 836-1885, or email info@jrclancy.com. About the photo attached: This frayed wire rope is barely attached to the winch. There should be a minimum of three dead wraps around the drum.

Take JR Clancy’s SureLock For A Test Drive

Counterweight rigging system runaways can be a serious problem backstage. The SureLock is an effective way to prevent runaways. To try out the SureLock, contact your local JR Clancy dealer to try it out in your space for 60 days.

Counterweight rigging system runaways can be a serious problem backstage. The SureLock is an effective way to prevent runaways. To try out the SureLock, contact your local JR Clancy dealer to try it out in your space for 60 days.

This is a great upgrade for existing counterweight systems in schools. Offering customers a free trial (possibly as part of an inspection) is a great way to promote safety. Call us if you’d like to borrow one. Additional SureLock information can be found at www.jrclancy.com.

When you are at a theatre that has had a runaway, it’s time for a training session and to explain why buying SureLocks could be a sensible investment in safety.

The SureLock is part of a complete safety plan. For more information on safety plans, visit www.promotesafesets.com for information on “Train – Inspect – Maintain”. This site has a great deal of good information, and suggests that end users take a look, especially to assist them in developing their own plans.

A functional loading gallery and proper training are essential for all manual counterweight rigging systems, including systems with SureLocks.

For more information, or to test drive a SureLock, contact Eric McAfee or your local JR Clancy dealer.

JR Clancy Makes “Hiding” Rigging Chain Easier with AlphaChain

We have all been there. We have needed to rig something to hang and had to use some trim chain. But the standard trim chain is a shiny silver surface so we had to spray paint it black to help mask it. Talk about time consuming!

We have all been there. We have needed to rig something to hang and had to use some trim chain. But the standard trim chain is a shiny silver surface so we had to spray paint it black to help mask it. Talk about time consuming!

JR Clancy has heard your cries for help and has introduced AlphaChain. It is designed specifically for theatrical and entertainment rigging. At first glance you’ll see the difference between AlphaChain and regular trim chain… AlphaChain is black!

Key Features of AlphaChain:

- Black chain eliminates glare and reflection

- Hardened alloy chain, meeting OSHA requirements for sling usage, OSHA 1910.184(e)(5)

- 3.250 lb. working load limit (based on manufacturers 4:1 safety factor)

- 7mm chain

- used with standard 1/4″ hardware

- Marked with JRC on every link

- Date code on every 10th link for traceability

There are three options when ordering the AlphaChain from JR Clancy

- 36″ Black Trim Chain with 5/16″ shackle and 1/4″ thimble (015-1191B)

- 36″ Black Trim Chain with 1/4″ shackle and 1/4″ thimble (015-1192B)

- 36″ Black Trim Chain with 1/4″ shackle and 3/6″ thimble (015-1193B)

Learn more about JR Clancy’s AlphaChain by visiting their web site at www.jrclancy.com.

J.R. Clancy Hosts Raynok Motion Control System at #LDI2010

Visitors to the J. R. Clancy, Inc. booth (#1227) at LDI this week will see a special guest: an exciting motion control system offered by Niscon.

Visitors to the J. R. Clancy, Inc. booth (#1227) at LDI this week will see a special guest: an exciting motion control system offered by Niscon.

Niscon’s Raynok MK2 Motion Control System can be configured to control a virtually unlimited number of axes from a variety of manufacturers’ equipment, including J. R. Clancy’s PowerLift and custom hoists. Raynok simplifies the collaborative efforts of the creative and technical teams to create fluid scenic imagery—from the simplest chain hoist system to the most complex turning, pushing or pulling application. Dual processors with live backup, a solid state hard drive, and redundant power supplies provided added reliability and safety.

In addition to Raynok, J. R. Clancy will showcase its own Altus theatrical rigging controller, designed for mid-level backstage rigging systems with up to 48 hoists. Altus provides touch-screen programmable capabilities that allow users to create up to 200 cues with different speeds and targets for each hoist.

LDI attendees can also see PowerAssist, the Clancy hoist that turns manual counterweight rigging into motorized linesets. Now in use in dozens of schools and colleges as well as in professional theatres, PowerAssist takes the guesswork out of balancing manual rigging, making it easier and safer for people with limited experience to use these linesets.

JR Clancy’s Factory – There’s ALWAYS Something Exciting Happening

Just about every day, there’s something unusual in production at JR Clancy’s plant in Syracuse, NY. Today, for example, they have got a gear motor that’s over five feet high – going into a new performing arts center. There’s also a new self-climbing truss being assembled this week.

Just about every day, there’s something unusual in production at JR Clancy’s plant in Syracuse, NY. Today, for example, they have got a gear motor that’s over five feet high – going into a new performing arts center. There’s also a new self-climbing truss being assembled this week.

At other times, they might be building stage lifts, custom hoists, or doing destructive testing – there is always something interesting going on there! When I visited the plant early last spring, I was FLOORED! I personally have never been up close and personal with rigging equipment of this size, but this is nothing new for JR Clancy, just another day at the office for them. But they don’t treat that way, each project is special and gets just as much love and attention as the small stuff like header blocks or any other rigging component that JR Clancy fabricates in-house.

Off the factory floor, JR Clancy is always trying to destroy something that they make. Their philosophy, it’s better to break it here then on stage. They do this for a very good reason, to find the safe working load for all of their products then they take it to the extreme, let’s see what it takes to have a failure, in a controlled manor of course. Destructive test as just another way that JR Clancy ensures that their products and services hold up to the demands of the entertainment industry.

J. R. Clancy Becomes an ETCP Training Provider

J. R. Clancy has been approved to become an official Training Provider in rigging, as designated by the Entertainment Technician Certification Program.

J. R. Clancy offers a training program that can assist ETCP Technicians in acquiring ETCP Renewal Credits towards recertification. Rigging professionals who take courses offered by J. R. Clancy earn one renewal credit per hour of instruction. The Clancy program began with one course; now, as an ETCP Training Provider, Clancy has expanded its program with multiple courses. Those interested in taking an industry certification examination may find these courses helpful in preparation.

Candidates who wish to sit for an ETCP examination must meet eligibility requirements. A total of 30 credits are required to qualify for the certification exam, with points awarded for work experience and college-level degrees earned. If you are interested in becoming certified, please visit http://etcp.esta.org.

“We were the first company to offer financial support for the ETCP rigging certification program when it was in its formation stage,” said Mike Murphy, J. R Clancy president. “We believe in the program’s goal: to create a more knowledgeable industry of highly skilled professionals, and a safer working environment for everyone backstage and onstage.”

J. R. Clancy also encourages ETCP rigging professionals to maintain their certification. In addition to paying the first-time testing fee for the employees of its dealer partners, the company now pays the recertification fee as well. To arrange for payment of the recertification fee, dealers can contact Jenn at J. R. Clancy at (800) 836-1885.

Several programs are now in development; topics and dates will be announced on the ETCP news page. More information about J. R. Clancy is available at www.jrclancy.com.

.

JR Clancy on Facebook, Show Us Your Scariest Rigging Photos

In JR Clancy’s latest Rigging Report email, they are calling for photos. No, not photos of your beautiful self, but photos of scary rigging. We have all been then. We have walked into a theatre, looked up and had to do a double take. “Are they really hanging pipes with dog chain?!?” Yup, I have seen that done and I RAN.

If you are like me, you take photos of these scary situations to show friends and co-workers just how un-safe that space is. JR Clancy is looking for those photos to add to their Facebook page. The collection of photos is not intended to make fun or laugh at a venue, but to serve as a remind why annual rigging inspections are so so important. Life would not be good if a schedule 40 pipe came crashing down from ANY height.

Dig through your scary rigging photos and be sure to add them to JR Clancy’s Facebook page to shed some light on some of the scariest rigging out there. And yes, you can withhold your name and venue location by contacting JR Clancy to add the photo for you.

UPDATE:

In response to one of our readers comments, JR Clancy wanted to follow up about scary rigging photos of their products as well. Here is what Patrick Finn from JR Clancy has to say:

This is Patrick Finn from J.R. Clancy. We want to see scary rigging photos of our equipment most of all. We can have fun posting the scary rigging photos on Facebook because we know that shortly after the shots are taken the issues are corrected. Please send me some pictures and let me know what theatre you are referring to. If this is an old system we can recommend an ETCP certified rigger who can inspect and repair the issues, and if this is a new installation the equipment may be under warranty. We want to know about all Clancy equipment installation good and bad so we can we address any issues. Thanks and I look forward to seeing your scary photos.

Hug a Arbor, It’s Arbor Day!

Today is the last Friday in April, that means it is Arbor Day! It is the day were we stop and hug our arbors, thank them for their hard work. Just kidding, that would be kinda funny though if it were true. Personally, I love Arbors! They hold all the weight to keep pipes flying in and bonking me on the head! JR Clancy wants to spread a little history safety about theatrical arbors even though today is suppose to be about trees. ;)

Today is the last Friday in April, that means it is Arbor Day! It is the day were we stop and hug our arbors, thank them for their hard work. Just kidding, that would be kinda funny though if it were true. Personally, I love Arbors! They hold all the weight to keep pipes flying in and bonking me on the head! JR Clancy wants to spread a little history safety about theatrical arbors even though today is suppose to be about trees. ;)

Let’s learn a little bit about the history of Arbors and how to safety operate them from JR Clancy and their most recent Rigging Report Email.

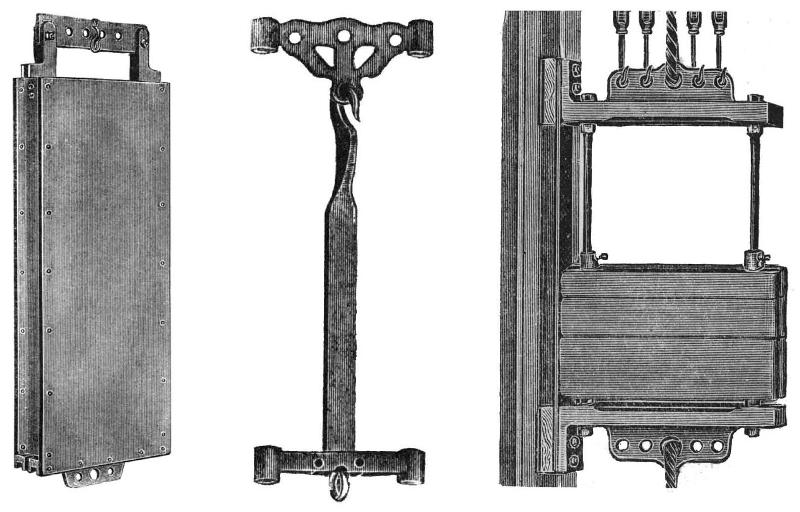

Clancy introduced their first counterweight arbors in 1905. These included several open single rod arbors as well as a sheet metal enclosed arbor. In 1921 the dual rod arbor was introduced, and remains today as the mostly widely used arbor.

Interestingly, the sheet metal arbor was the first to be discontinued, while the open arbor has been in use for 85 years and is still used in most rigging systems today. There is a reason for this – it’s a solid design, using standard counterweight, with an excellent weight retention system, and it’s easy to load and unload. We’re big on continual improvement and testing. Several years ago we spent a summer “crashing” arbors – in both directions – to analyze weak spots. As a result of these tests, we incorporated some new ideas.

Structural Integrity

Structural Integrity

The arbor top is a single piece of folded 1/4″ steel plate. It’s sturdy and doesn’t require any welding. You can rely on the integrity of the Clancy arbor. There’s even a tab at the front for the lineset number.

An Effective Set Screw

An Effective Set Screw

The traditional set screw is hard to tighten properly, and can slip in a crash. That’s not acceptable. Clancy set screws have three advantages:

- The high-visibility red handles are easy to tighten without tools. (You can even tighten it wearing gloves).

- The screw uses fine thread for higher strength and, reducing the temptation to “borrow” the set screws for other uses.

- The screw has a dog tip, which gets a great grip on the arbor rods, for much better retention.

Spreader Plates

Spreader plates are one of the keys to backstage safety. The backbar has indicators showing where the spreader plates should be placed. The top spreader plate is welded to the front collar to ensure there is always a spreader plate at the top of the counterweight stack.

In our tests of intentional crashes, the arbors retained the weights when the spreader plates and set screws were used properly.

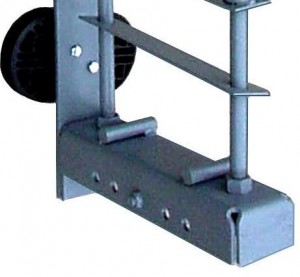

Arbor Bottoms

Arbor Bottoms

Again, you’ll get a robust, folded, one piece steel piece for security. Welded spacers support the counterweight stack so they don’t rest on the arbor rod nuts.

Guide Shoe

The guide shoe can be used on guide systems from 6″ to 8″ by simply rotating the shoe.

Reduced Installation Costs

Clancy arbors are shipped fully assembled (even the guide shoes) to reduce time on site. The pre-assembled guide shoe also reduces installation time and costs. The shoes don’t need to be removed to install the arbors.

LatestHeadlines

- Upgrading Your Toolbox: City Theatrical DMXcat-E and DMXcat Multi Function Test Tool

- Claypaky Bringing Back the Sexy to Par Cans with the Midi-B FX

- Ayrton Evolves the Cobra, the Cobra2 Developed for the US Market

- MA Lighting Intros grandMA3 onPC Fader Wing and DIN-Rail Nodes

- Live Events LEVL Up Fest: A Festival to Aid our Industry