Ron StageMaster 6000 G4 Wireless & Wired Shackle Pin Load Cell

Eilon Engineering Offers New Ron StageMaster 6000 G4 Wireless and Wired Shackle Pin Load Cell

Talk about a mouth load! With heavy loads above our heads and safety on every ones mind, monitoring the weight of truss has be come an inportant topic in the industry. Eilon Engineering offers a new load cell monitoring system that is built right into the shackle for ease of use. If you are one of those that don’t truss wireless signals for an important task such as load monitoring, have no fear, the new Ron Stagemaster 6000 is offered in both wireless and wired.

Here is more from Eilon Engineering:

Eilon Engineering announces launch of the new Ron StageMaster (RSM) 6000 G4 Wireless and Wired Shackle Pin load cell for load monitoring and overload prevention. The advanced load cell features a new shackle pin design that makes it ideal for applications where headroom is extremely limited while its wireless capability makes for a quicker installation.

The RSM 6000 G4 Shackle Pin load cell includes a 5/8″ standard shackle enabling an extremely low headroom loss of only 2.4 inches (61mm), especially important in indoor applications where ceiling height is often an issue. Made of aerospace quality, high-strength alloy steel, the RSM 6000 G4 Shackle Pin load cell, like all Eilon Engineering load cells, is fatigue rated to withstand unlimited load cycles without the risk of failure or damage to the steel. The RSM system features continuous monitoring up to 5000 hours (10,000 hour battery life option), and unlike other systems on the market contains absolutely no standby or sleep modes, which are risky and unacceptable from a safety perspective.

Safety above all

In addition to the fatigue-rated load cells and continuous monitoring up to 5000 hours, the RSM system includes a raft of other safety features including independent data flow and multi-channel transmission, as well as internal verification, an internal safety check that ensures the displayed data is always an exact match with that being transmitted by the load cells. An extended transmission range up to 2km adds an additional layer of safety. Furthermore, Ron StageMaster load cells work with any motor control system to provide automatic emergency stop (E-stop) and overload/under-load alarm (visual and audible).

Ease of operation and setup

The IP 65-rated system communicates wirelessly to a PC laptop via a receiver, eliminating messy cabling and lengthy setup time. The result is a quick-to-install plug and play system, essential in many facets of the entertainment industry like tours and on-the-road productions. And thanks to a Slave-Master option, a nearly unlimited number of load cells can be used.

Real-time monitoring

The laptop-based Ron StageMaster safety system features real-time monitoring of all loads from a single screen and from any location. And for simple integration with the plot, the RSM system software allows for overlay of the load map right onto the plot on screen, making it easy to see where motors, weight, etc. are on the plot. This enables the rigger to immediately identify the location of an overload and take swift preventative action. In addition, the set point option enables immediate motor stop in case of an overload. The system provides a record at the end of the show, is compatible with smart phones and tablets and can even send SMS alerts.

RSM compatibility

The RSM 6000 G4 Wireless and Wired Shackle Pin load cell is compatible with all Eilon RSM G4 systems (wired and wireless), including the Ron StageMaster Classic and the recently launched Ron StageMaster Hoist Integrated load cell.

For more details visit www.eilon-engineering.com

JR Clancy Offers New Rigging Hoists; PowerLine, StageHand, StageHand+, Titan

JR Clancy continues to evolve the world of stage rigging and motor control with their latest line of products. JR Clancy just announced four new products to their lineup. The PowerLine Line Shaft Hoist, StageHand Manual Hoist, StageHand+ Motorized Hoist and the Titan Automated Hoist.

PowerLine

PowerLine

The PowerLine provides a wide range of speeds and capacities, making it a versatile performer. Applications include scenery, lighting sets, curtains, and front-of-house lighting. These hoists have minimal side loading on the building structure, simplifying building steel and making these hoists excellent for retrofits in older buildings. Learn more about the PowerLine Line Shaft Hoist by downloading the spec sheet.

StageHand

StageHand

StageHand you get extraordinary lifting capacity for an economical price. Manual utility hoists for access to lighting sets, masking curtains, and other items that do not move as part of a performance. The hoist can be padlocked for security. The StageHand hoist shall not be used to lift humans. Learn more about the StageHand Hoist by downloading the spec sheet.

StageHand+

StageHand+

StageHand+ you get extraordinary lifting capacity for an economical price. A motorized utility hoists for access to lighting sets, masking curtains, and other items that do not move as part of a performance all at the push of a button. The hoist can be padlocked for security. The StageHand hoist shall not be used to lift humans. Learn more about the StageHand Hoist by downloading the spec sheet.

Titan

Titan

Clancy has been building big, custom performance hoists for many years. The Titan hoist is a semi-custom hoist providing high speed and high capacity in a compact package. These performance hoists are used in major performing arts centers, opera houses, and concert halls. Learn more about the Titan Hoist by downloading the spec sheet.

You can always visit JR Clancy’s website at www.jrclancy.com to learn more and to get system quotes.

Shock Boxx – Shock System for Lighting Truss

Kai Knox Technologies and Scott Almand Designs today announced the launch of Shock Boxx, the first-ever pre-rig lighting truss shock system. This breakthrough product protects expensive truss-mounted lighting and video equipment as it’s transported around the world, finally providing a solution to a common and costly challenge for the touring market.

Kai Knox Technologies and Scott Almand Designs today announced the launch of Shock Boxx, the first-ever pre-rig lighting truss shock system. This breakthrough product protects expensive truss-mounted lighting and video equipment as it’s transported around the world, finally providing a solution to a common and costly challenge for the touring market.

This revolutionary, “patent pending” technology is the result of a collaboration between Heather Roberts of Kai Knox Technologies and Scott Almand of Scott Almand Designs. Their combined 30 years experience in the entertainment industry and their passion for meeting client needs with innovative solutions inspired them to design Shock Boxx.

A Shock Boxx unit is comprised of a box-shaped carriage system, a shock system, and locator bars. First, the carriage system is positioned snuggly inside the pre-rigged truss. Then the shocks are installed on the sides of the truss. Finally, the locator bars are positioned in the desired location of the lighting fixtures. Integrating Shock Box into existing truss inventory is fast and convenient—the easy-to-assemble retrofit kit can be installed in less than ten minutes.

Available in multiple configurations and sizes, Shock Boxx is compatible with any standard pre-rig truss (26 in. x 30 in.) or HUD/GT truss (14 in. x 24 in.) system. Shock Boxx begins shipping on July 1st and pre-orders are being accepted now. For more information, visit www.shock-boxx.com.

Lex Products Adds Molded Motor Control Cables to EverGrip Line

Lex Products announces the addition of Molded 7 and 14 Pin Motor Control Cable to its growing line of EverGrip cable assemblies. Lex’s overmold technology provides enhanced safety and durability for critical motor and hoist applications used in Entertainment scenery and rigging. The cables feature 7 and 14 pin Veam compatible quarter turn motor configuration connectors and heavy-duty 16AWG 7 conductor SOOW cable.

Lex Products announces the addition of Molded 7 and 14 Pin Motor Control Cable to its growing line of EverGrip cable assemblies. Lex’s overmold technology provides enhanced safety and durability for critical motor and hoist applications used in Entertainment scenery and rigging. The cables feature 7 and 14 pin Veam compatible quarter turn motor configuration connectors and heavy-duty 16AWG 7 conductor SOOW cable.

The core of EverGrip is a polypropylene premold which provides a mechanical bond between the cable and connector and totally encapsulates the contacts and conductors to prevent the possibility of pushed pins, and broken conductors. Short circuits due to stray wires are eliminated. A solid Santoprene overmold absorbs impact to protect internal conductors and provides enhanced flex and strain relief to extend cable life.

Standard length cable assemblies are available from 5ft. thru 200ft. Custom cable lengths and cable labels can also be specified. Lex can also retrofit new EverGrip molded connectors to your damaged motor cables, extending the life of your cable.

To help reduce potential losses do to mixing of dealers cable on job sites and to increase dealers brand identity, the customer’s name or logo can be molded into each connector body for a nominal charge.

Lex offers a 5 year limited warranty on EverGrip molded male and female connectors. Lex also molding of names and logo’s on the connectors of the cables. To learn more about the new Molded Motor Control Cables, visit Lex Product’s website at www.lexproducts.com.

XLNT Advanced Technologies Announces XLNT CyberMotion Motion Control System

XLNT Advanced Technologies just announced their latest product at ProLight + Sound in Frankfurt Germany, the XLNT CyberMotion control system. XLNT CyberMotion offers a complete range of motion products designed specifically for the entertainment industry. Developed by XLNT Advanced Technologies, SIL3 certified state of the art technology was used to create a unique series of intercompatible road-ready products for breathtaking shows and cost efficient global touring.

XLNT Advanced Technologies just announced their latest product at ProLight + Sound in Frankfurt Germany, the XLNT CyberMotion control system. XLNT CyberMotion offers a complete range of motion products designed specifically for the entertainment industry. Developed by XLNT Advanced Technologies, SIL3 certified state of the art technology was used to create a unique series of intercompatible road-ready products for breathtaking shows and cost efficient global touring.

Intelligent, variable speed chain hoists, winches, trolley beams and other motion control mechanics, instantly add movement and velocity to permanent installations, multi-purpose venues, concert touring and theatre, TV or event productions of any size.

A convenient integrated truss concept significantly reduces load volumes, the time needed for set-up and tear-down and the required number of onsite staff. All XLNT CyberMotion products are multi-voltage and suitable for global use. The plug & play CyberMotion system provides a choice of two intelligent, variable speed chain hoists, the XLNT CHII-Hoist, for world-wide touring and spectacular shows, and the XLNT C-Hoist, designed for multi-purpose venues, permanent installation and theatres.

The XLNT C-Winch is an intelligent, high-speed winch for ultra-fast lifting and movement of lightweight objects with 0.1 mm positioning accuracy. XLNT C-Track and XLNT C-Trolley provide a versatile, wide beam monorail track system suitable for truss suspension and floor mounting, with a wireless trolley system for spectacular 3D movement.

Complementing all these is XLNT C-Truss, smart, dedicated truss solutions to integrate XLNT CyberMotion products into a grid concept and maximize headroom. C-Truss increases return on investment by reducing set-up and tear-down times and optimizing logistics.

Providing programming and show control is the new, dedicated XLNT MotionCue3D, an intuitive front-end operating console for intelligent, object oriented programming of complex 3D objects with 0.1 mm accuracy, using CAD and animation software. It provides real-time 360° view and position tracking and allows freely assignable points of rotation per object or cue.

Finally, distributing the system’s power and data respectively are XLNT C-Power, solid-state power distribution in durable steel housing, and XLNT DataMotion, a road-proof and reliable Ethernet data distribution to keep equipment working under all circumstances.

As well as being SIL3 Certified CyberMotion is compliant with all international safety standards and codes of practice (EN61508, DIN56950, BS, FEM, UL), built using industrial grade technology to last and perform with a tireless duty cycle, and features practical, compact design.

XLNT Advanced Technologies is an international company, solidly grounded in the entertainment industry. Our passion for technology and experience in entertainment form a solid foundation for the products we design and manufacture. We focus on innovations that will broaden creative horizons and meet uncompromising needs for safety and touring while increasing return on investment.

JR Clancy to Showcase Rigging Projects at USITT in Charlotte

The very latest in rigging technology—from award-winning innovations for a grand opera house to the safest choices for schools—will be showcased in videos at J. R. Clancy’s booth (#730) at the USITT conference in Charlotte, NC, March 9-12, 2011.

J. R. Clancy will feature high-resolution videos of several of its most recent rigging projects in action:

1. The custom-built, 40-foot-high chandelier in the Winspear Opera House in Dallas features 318 cast acrylic rods which vanish as the house lights dim before a production begins. Clancy technology made it possible for the rods to move in synchronized patterns and retract into the ceiling smoothly and rapidly, powered by 44 custom-design winches with up to eight lines per winch. The video provides close-up views of the intricate rigging above the house ceiling while the chandelier’s rods are in motion.

2. Clancy’s PowerAssist™ allows you to motorize new or existing counterweight sets economically. This eliminates handling counterweights, simplifying operations. PowerAssist can be provided with Up / Down pushbuttons, or with the SureTarget™ preset position controller. These are widely used on lighting and orchestra shell ceiling sets where accurate positioning is essential.

3. Imagine changing over from a dance concert’s scenery to an orchestral shell and acoustic canopy in just 47 minutes—using a student crew! At the Miller Performing Arts Center at Alfred University, Clancy’s PowerLift automated rigging system makes even the most complex changeovers easy. You’ll see students operate the PowerLifts using Clancy’s top-of-the-line SceneControl 500 rigging control console, removing dance concert scenery from battens without moving a single counterweight, and hanging pieces of the Wenger Diva shell effortlessly. Preset limits for each batten return the shell to the correct position.

More on J. R. Clancy is available at www.jrclancy.com.

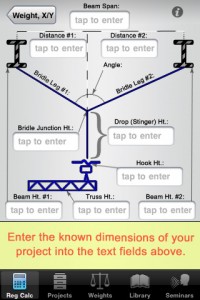

iOS App: Event Rigging Helper

Do you handle equipment over peoples heads? It can be a tough and exhausting job. You have a lot information in your head that you need to put together to make sure that rig is safe and secure.

Do you handle equipment over peoples heads? It can be a tough and exhausting job. You have a lot information in your head that you need to put together to make sure that rig is safe and secure.

Doing a bit of searching yesterday, I ran across another industry iOS app, Event Rigging Helper. Plug in some information and it help calculate jumps, bridles, lengths and more. The app also can keep track of your projects, a library of truss manufacturers, hoist, winches and other assorted equipment a rigger might need info on.

Features include:

•Bridle Length calculator (imperial, metric, ratio)

•Leg tension calculator

•Multiple Project data- notate per show, venue, elements, trim, purpose, point location

•Track show weight: totals per point, per element, per show

•Export data

•Record keeping

•Weight database of typical production elements

•Library of manufacturer’s product spec’s in the likes of truss and motors, shackle, cable, power distribution…

•Rigging education and seminar info…

•Industrial Rope Access info

•Venue data contribution and exchange

•Facebook page for community, discussion and dialog

The Event Rigging Helper App does not come cheap in comparison for most iOS apps. The app cost $19.99 USD through the iTunes App Store. I am not saying that the app is over priced. What I am saying is if you fell that paying $19.99 for an app that help you save time and money on the job… Then it just might be worth the investment.

REMEMBER: Purchasing and or using this app does NOT make you a rigger. Rigging should be performed under the supervision of experienced and certified professionals.

JR Clancy Supports “Roadie for a Day” Boot Camp in Dallas

Have you always wanted to be a roadie? It is a tough life! How would you like to live the life for a day? At this year’s Performing Arts Managers Conference, (PAMC) in Dallas Texas, that dream can come true with the “Roadie for a Day” Boot Camp on Saturday, February 26th.

JR Clancy is leading the sponsorship on the event which will be held at the AT&T Performing Arts Center as part of the International Association of Venue Manager, (IAVM) and the annual PAMC conference. The Boot Camp will be lead by Millie Dixon, principal consultant at Theatre Projects Consultants and the Boot Camp leader, and Alex Hargis, manager of the Wyly Theatre at the AT&T Performing Arts Center. J.R. Clancy personnel and partners also will lead the rigging section to ensure that participants learn the correct and safe way to plan, assemble, and operate standard touring rigging equipment.

For an intensive afternoon, from 12 noon to 4:30 p.m., three teams-each including 20 to 30 venue managers-will learn how to set rigging points, load-in and assemble truss, chain motors, and control equipment, and safely prepare the ‘rig’ for the attachment of the lighting and touring equipment load-in. In addition, team members will hang and cable lights, complete the circuiting, and design two different lighting “looks” on the venue stage.

Each team will work in its own venue at AT&T Performing Arts Center: Margaret McDermott Performance Hall, Hamon Hall in the Bill and Margot Winspear Opera House, and the Dee and Charles Wyly Theatre.

For more information visit www.iavm.org.

ETC Releases New iPad App – ETC Rigging

The ETC Rigging app is an interactive tool for demonstrating the unique aspects of ETC’s line of rigging products. Users can experience the benefits of the compact Prodigy™ hoist system, or find out how the ETC’s compression tube system can save money when planning new construction or renovating an existing venue. The app demonstrates how ETC’s cable management system tucks neatly away and how the user-friendly QuickTouch™ control system works. More information about ETC’s rigging line can be found at www.etcrigging.com.

The ETC Rigging app is an interactive tool for demonstrating the unique aspects of ETC’s line of rigging products. Users can experience the benefits of the compact Prodigy™ hoist system, or find out how the ETC’s compression tube system can save money when planning new construction or renovating an existing venue. The app demonstrates how ETC’s cable management system tucks neatly away and how the user-friendly QuickTouch™ control system works. More information about ETC’s rigging line can be found at www.etcrigging.com.

You can download the FREE app from the iTunes App Store.

James Thomas Engineering Introduces X Truss

James Thomas Engineering is preparing to launch a new series of truss called X Truss. It’s not just another form of truss, but a response to what the industry has been asking for as well as a carbon neutral product.

James Thomas Engineering is preparing to launch a new series of truss called X Truss. It’s not just another form of truss, but a response to what the industry has been asking for as well as a carbon neutral product.

From Wikipedia: Carbon neutrality, or having a net zero carbon footprint, refers to achieving net zero carbon emissions by balancing a measured amount of carbon released with an equivalent amount sequestered or offset, or buying enough carbon credits to make up the difference. It is used in the context of carbon dioxide releasing processes, associated with transportation, energy production and industrial processes.

X Truss is fully compatible with 52cm SuperTruss and uses the same overall sizes and connection methods of the existing technology. This means all existing 52cm SuperTruss Gates, plates and corners are compatible with X Truss; X Truss can be mixed in the same system as 52cm SuperTruss (excluding within the same span); and X Truss can be used with existing ground support towers and sleeve assemblies.

TOMCAT Announces 18th Annual Hoist & Rigging Workshop Feb. 16-19 in Texas

TOMCAT’s 2011 ETCP Hoist & Rigging workshops are less than 3 weeks away, February 16-19 in Midland, Texas. Registration is still open for those interested in improving their skills and prospects for 2011 and beyond with training on chain hoists or rigging principles. The schedule is finalized and includes a team of world-class instructors to provide a hands-on-learning experience to production professionals across North America. More information on the workshops in Midland can be found at www.tomcatglobal.com.

TOMCAT’s 2011 ETCP Hoist & Rigging workshops are less than 3 weeks away, February 16-19 in Midland, Texas. Registration is still open for those interested in improving their skills and prospects for 2011 and beyond with training on chain hoists or rigging principles. The schedule is finalized and includes a team of world-class instructors to provide a hands-on-learning experience to production professionals across North America. More information on the workshops in Midland can be found at www.tomcatglobal.com.

The Hoist & Rigging workshops schedule includes instruction by respected and recognized leaders in the industry. Both training tracts include instruction on truss design, usage and theory with Will Todd, TOMCAT USA’s Product Support Manager. Keith Bohn, TOMCAT USA’s Custom Projects Director, will lead a session on design and safe use of ground supported structures. The first day of training will conclude with an introduction to entertainment automation by Kevin Taylor, CEO of Stage Technologies.

Attendees in the Hoist & Truss tract will start with a training session on hoist control systems let by Kevin Taylor of Stage Technologies. Participants will then get dirty with Dave Carmack of Columbus McKinnon, who will provide hands-on motor instruction including teardown, re-assembly, maintenance and live troubleshooting. This group will conclude its training by taking CM’s certification exam.

In the Rigging & Truss workshop, ETCP certified rigger and instructor G. Anthony Phillips of RigRider Rigging Services will teach safe rigging practices and principles, while Morgan Neff, Fall Protection expert will instruct on safe fall protection practices. Participants will also have the opportunity to put these principles into live practice.

Take JR Clancy’s SureLock For A Test Drive

Counterweight rigging system runaways can be a serious problem backstage. The SureLock is an effective way to prevent runaways. To try out the SureLock, contact your local JR Clancy dealer to try it out in your space for 60 days.

Counterweight rigging system runaways can be a serious problem backstage. The SureLock is an effective way to prevent runaways. To try out the SureLock, contact your local JR Clancy dealer to try it out in your space for 60 days.

This is a great upgrade for existing counterweight systems in schools. Offering customers a free trial (possibly as part of an inspection) is a great way to promote safety. Call us if you’d like to borrow one. Additional SureLock information can be found at www.jrclancy.com.

When you are at a theatre that has had a runaway, it’s time for a training session and to explain why buying SureLocks could be a sensible investment in safety.

The SureLock is part of a complete safety plan. For more information on safety plans, visit www.promotesafesets.com for information on “Train – Inspect – Maintain”. This site has a great deal of good information, and suggests that end users take a look, especially to assist them in developing their own plans.

A functional loading gallery and proper training are essential for all manual counterweight rigging systems, including systems with SureLocks.

For more information, or to test drive a SureLock, contact Eric McAfee or your local JR Clancy dealer.

LatestHeadlines

- Upgrading Your Toolbox: City Theatrical DMXcat-E and DMXcat Multi Function Test Tool

- Claypaky Bringing Back the Sexy to Par Cans with the Midi-B FX

- Ayrton Evolves the Cobra, the Cobra2 Developed for the US Market

- MA Lighting Intros grandMA3 onPC Fader Wing and DIN-Rail Nodes

- Live Events LEVL Up Fest: A Festival to Aid our Industry