Gearhouse In2Structures Launches Combi Dome

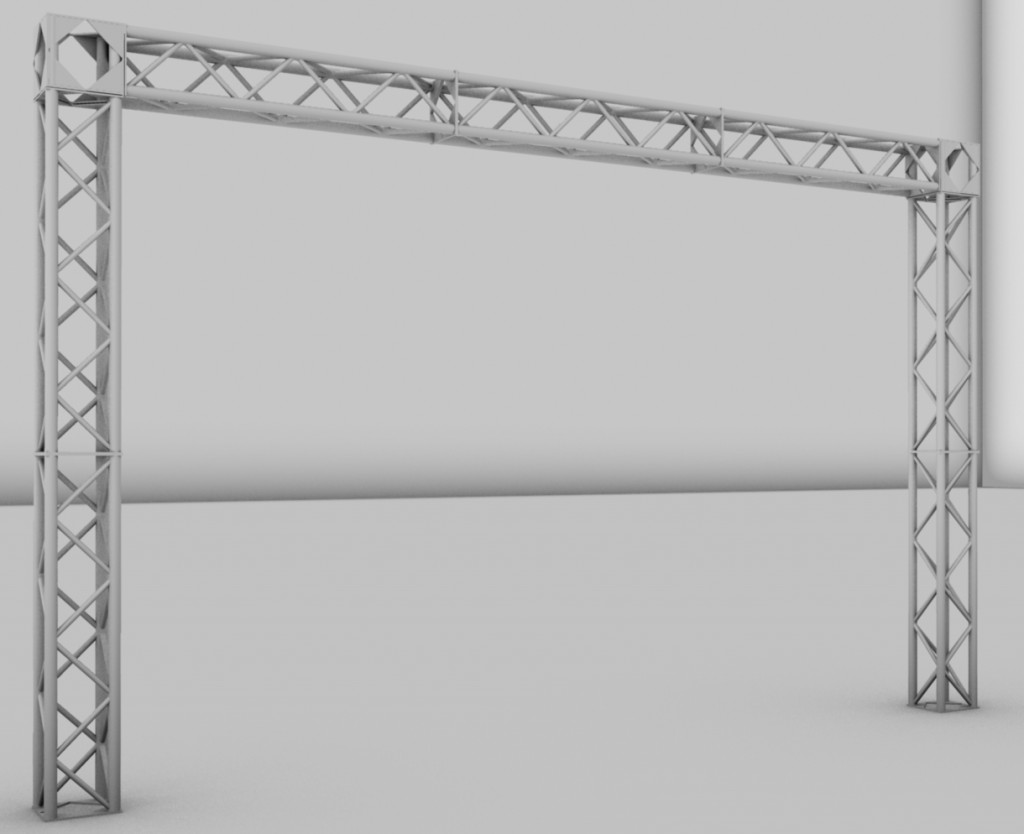

Combining movability with great aesthetics and flexibility, the COMBI DOME is the latest In2Structures’ range of steel framed Domes and is ideal for all types of events. The range also includes the larger Maxi and Supa Dome versions. With its 20 meter width, the COMBI DOME is the perfect complement to these larger venues which stand at 28 and 36 meters wide respectively. Length is added or subtracted to the COMBI DOME with 4 meter ‘Bays’, and different colored Teflon skins – including transparent and customized – can be supplied as required.

Combining movability with great aesthetics and flexibility, the COMBI DOME is the latest In2Structures’ range of steel framed Domes and is ideal for all types of events. The range also includes the larger Maxi and Supa Dome versions. With its 20 meter width, the COMBI DOME is the perfect complement to these larger venues which stand at 28 and 36 meters wide respectively. Length is added or subtracted to the COMBI DOME with 4 meter ‘Bays’, and different colored Teflon skins – including transparent and customized – can be supplied as required.

Designed as a ‘compact’ venue, COMBI DOME still has a serious load capacity of 1500 Kgs per arch – which will facilitate a good amount of production equipment, and the structure is certified to withstand wind speeds of up to 120 kmh. The rigging height of 9 meters makes it ideal as an events venue … and for a rental company, one COMBI DOME can also be used as two very attractively shaped stage roofs.

It can be built as a variety of shapes and sizes with the option of attachable ‘mini’ Domes that can be utilized for miscellaneous working areas like dressing and green rooms, kitchens, foyers or storage spaces. It can be erected in 2 or 3 days with the aid of a small 8 tonne truck crane. Specialist elements unique only to In2Structures’ creations include the bespoke leveling system, novel doors and entrance installation technology.

Apart from temporary and semi-permanent applications, COMBI DOME is also a highly cost effective option for permanent installations with a very reasonable square metreage cost. The 6 bay version of the COMBI DOME deployed for the launch event offered a sizable 19 meter by 43 meter internal working space with an airy 9 meter apex.

Squint Abroad – Load In

Loading in any event can be stressful. Even when you are not dealing with language barriers, unfamiliar electrical standards, and different gear, the ballet of people and gear is a delicate balance between executing “the plan” and adapting to challenges. In a foreign country this process has the potential to be a disaster. Luckily, my experience abroad has been nothing but positive. This week we are in Istanbul, Turkey building, running, and then tearing out a corporate event. Although our client will only spend around seven hours in the general session space, countless hours have been spent planning, designing, building, teching, and rehearsing every little detail.

Let’s talk about the load in experience. I’ll paint you a picture of what exactly we are working with

- A ball room space (width) by (length) with a (height) ceiling.

- An octagonal 8 screen projection setup, with a “T” shaped stage at the front

- Lighting and seven speaker surround audio support

Fortunately for us the in house A/V is a production house similar in capability and gear to our own company. While we have traveled with our entire video rig, including switching and projection, the audio and lighting gear came from the house. They were able to provide familiar Vari Lite 3000 fixtures, ETC Source 4’s. Our audio team was happy to have the same Yamaha console we use back in the states, as well as a pair of Labgruppen line array cabinets. Eight powered speakers hide behind each screen for full surround audio support. Perhaps most importantly they were able to provide the proper truss (Prolyte folding triangle) and motor package. This show relies on the 18 foot tall video walls in an octagonal shape, and being able to fly the rig instead of ground supporting is a huge advantage.

Working with the in house team was a breeze. They know their gear well, and could easily take our CAD drawings and implement without a problem. While we had issues with language barriers enough of their crew spoke English well enough to keep both of our production teams on the same page. Needless to say, it was a great opportunity, and we are all really excited for the next chance to work overseas!

Squint Abroad: Language Barriers

We understand from a basic study of history that cultural and language barriers have been points of contention and difficulty for thousands of years. Construction of the tower of Babel was halted when the masons were no longer able to communicate in the same tongue. It’s safe to say that in the event production industry, we have moved beyond language and use our common bonds as professionals to get a show up and running. We all abide by certain natural rules and regulations, and intuitively understand the same restrictions people and gear have.

A mere week ago, in Bangkok, Thailand, we were tasked with erecting eight truss structure with a crew of 20 local technicians. There was one individual on their team able to speak fluent English, yet we were able to build and raise all of the structures and move them into place with minimal verbal communication. Hand signals and normally meaningless guttural sounds took on the meanings “left, right, forward, back, go, or STOP!!!”. After a few hours, all eight structures were in place, and no one was injured in the process.

Truth be told, we had enough to deal with during the early stages of load in that the language barrier was never seen as a significant issue. The event was being held in a third floor hotel ballroom, in a building without a significant freight elevator. That meant 400+ feet of truss, baseplates, and outriggers were hand carried up stairs. Keep in mind, it’s more than 90 degrees during the day in Thailand this time of year. Needless to say, it was a challenge.

Everyone in our industry knows the difficulties that pop up on a show site, especially when project principals disagree on a given process or outcome of a decision during a load in. While somewhat rare, work stoppage wastes time and money. I’m sure that if either party in Thailand, our production team or the local gear house, had a reason to raise concerns over safety or process, flags would have been thrown. The language barrier created the opportunity to avoid any nit-picking and allowed us to get the job done in an incredibly short amount of time.

LatestHeadlines

- Upgrading Your Toolbox: City Theatrical DMXcat-E and DMXcat Multi Function Test Tool

- Claypaky Bringing Back the Sexy to Par Cans with the Midi-B FX

- Ayrton Evolves the Cobra, the Cobra2 Developed for the US Market

- MA Lighting Intros grandMA3 onPC Fader Wing and DIN-Rail Nodes

- Live Events LEVL Up Fest: A Festival to Aid our Industry