Today is the last Friday in April, that means it is Arbor Day! It is the day were we stop and hug our arbors, thank them for their hard work. Just kidding, that would be kinda funny though if it were true. Personally, I love Arbors! They hold all the weight to keep pipes flying in and bonking me on the head! JR Clancy wants to spread a little history safety about theatrical arbors even though today is suppose to be about trees. ;)

Today is the last Friday in April, that means it is Arbor Day! It is the day were we stop and hug our arbors, thank them for their hard work. Just kidding, that would be kinda funny though if it were true. Personally, I love Arbors! They hold all the weight to keep pipes flying in and bonking me on the head! JR Clancy wants to spread a little history safety about theatrical arbors even though today is suppose to be about trees. ;)

Let’s learn a little bit about the history of Arbors and how to safety operate them from JR Clancy and their most recent Rigging Report Email.

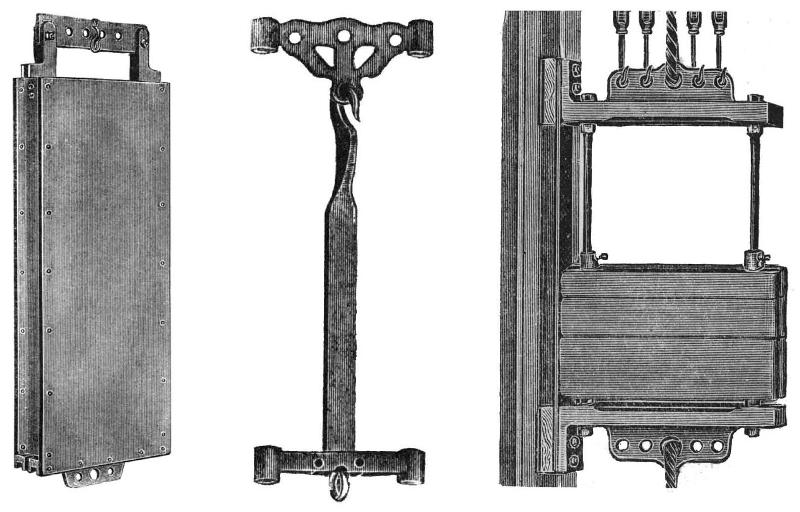

Clancy introduced their first counterweight arbors in 1905. These included several open single rod arbors as well as a sheet metal enclosed arbor. In 1921 the dual rod arbor was introduced, and remains today as the mostly widely used arbor.

Interestingly, the sheet metal arbor was the first to be discontinued, while the open arbor has been in use for 85 years and is still used in most rigging systems today. There is a reason for this – it’s a solid design, using standard counterweight, with an excellent weight retention system, and it’s easy to load and unload. We’re big on continual improvement and testing. Several years ago we spent a summer “crashing” arbors – in both directions – to analyze weak spots. As a result of these tests, we incorporated some new ideas.

Structural Integrity

Structural Integrity

The arbor top is a single piece of folded 1/4″ steel plate. It’s sturdy and doesn’t require any welding. You can rely on the integrity of the Clancy arbor. There’s even a tab at the front for the lineset number.

An Effective Set Screw

An Effective Set Screw

The traditional set screw is hard to tighten properly, and can slip in a crash. That’s not acceptable. Clancy set screws have three advantages:

- The high-visibility red handles are easy to tighten without tools. (You can even tighten it wearing gloves).

- The screw uses fine thread for higher strength and, reducing the temptation to “borrow” the set screws for other uses.

- The screw has a dog tip, which gets a great grip on the arbor rods, for much better retention.

Spreader Plates

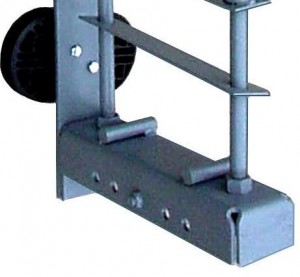

Spreader plates are one of the keys to backstage safety. The backbar has indicators showing where the spreader plates should be placed. The top spreader plate is welded to the front collar to ensure there is always a spreader plate at the top of the counterweight stack.

In our tests of intentional crashes, the arbors retained the weights when the spreader plates and set screws were used properly.

Arbor Bottoms

Arbor Bottoms

Again, you’ll get a robust, folded, one piece steel piece for security. Welded spacers support the counterweight stack so they don’t rest on the arbor rod nuts.

Guide Shoe

The guide shoe can be used on guide systems from 6″ to 8″ by simply rotating the shoe.

Reduced Installation Costs

Clancy arbors are shipped fully assembled (even the guide shoes) to reduce time on site. The pre-assembled guide shoe also reduces installation time and costs. The shoes don’t need to be removed to install the arbors.

LatestHeadlines

- Upgrading Your Toolbox: City Theatrical DMXcat-E and DMXcat Multi Function Test Tool

- Claypaky Bringing Back the Sexy to Par Cans with the Midi-B FX

- Ayrton Evolves the Cobra, the Cobra2 Developed for the US Market

- MA Lighting Intros grandMA3 onPC Fader Wing and DIN-Rail Nodes

- Live Events LEVL Up Fest: A Festival to Aid our Industry